Pretreatment: Fats, Oils and Grease (FOG) Program

The purpose of the Salt River Pima-Maricopa Indian Community’s FOG Program is to protect the sanitary sewer system and the treatment plant that receives the wastewater.

FATS, OILS AND GREASE (FOG) PROGRAM

Introduction

The purpose of this guideline is to aid Food Service Establishments (FSEs) in the Salt River Pima-Maricopa Indian Community to understand fats, oils and grease (FOG) and provide guidance in the selection of proper grease interceptor for facilities that have the potential to discharge FOG. All users of the SRPMIC wastewater collection systems are prohibited from discharging wastewater containing pollutants that will interfere with the operation of the wastewater collection systems and expose personnel to health or safety hazards.

Fog Program Overview

What is FOG?

FOG is a common term for the excess animal fats and cooking oils that are generated during cooking and in many food preparation steps. FOG enters the plumbing system through kitchen sinks and floor drains in food preparation areas. Over time, FOG sticking to the interior of pipes can lead to reduced hydraulic capacity or a complete sewer blockage. When that occurs, the result will ultimately trigger a sewage spill, also known as Sanitary Sewer Overflow (SSO). FSEs have long been known to have the potential to adversely impact the sewer system by discharging FOG-containing wastewater from their kitchens.

FOG blockage in sewer pipe

Why FOG is an issue?

FOG discharged by residential, commercial, institutional, and industrial users present a significant problem to the wastewater collection and treatment systems, causing sewer blockages resulting in sanitary sewer overflows (SSO).

For more information or questions on FOG, please contact Public Works, Water Resources Section:

The FOG Program at (480) 362-5600 or Email: PWWaterResourcesPretreatment@SRPMIC-nsn.gov

ROUTINE INSPECTION

Routine Inspection

The SRPMIC Public Works Department Water Resources Sections will perform routine inspection to educate, ensure compliance and gather records of routine maintenance of grease interceptors and grease traps.

The Inspector Will Require to See The Following:

- Grease Interceptor Maintenance Records and Yearly Log: To show the frequency of the interceptor pumping and cleaning. These records are to be kept on site for three (3) years.

- The Grease Interceptor: To check if any parts are missing or damage to the interceptor itself. To check how much grease is in the interceptor and if maintenance is required.

- The Kitchen Area: To document grease bearing fixtures in the facility, to determine if are any issues and document repairs that are needed.

- Outside: To ensure the areas are kept clean and no cooking oil or garbage is on the ground.

At the end of the inspection, the inspector will review the findings with the manager/owner and can provide educational materials and steps on how to better manage FOG.

If there are any issues identified as deficient, they will be documented during the inspection and the FSE will be required to correct the problem within a designated time frame. Our goal is to address compliance through cooperation. A time extension to correct deficiencies can be granted based on business needs and the request must be in writing.

For FSEs that repeatedly fail to comply and cause sewer blockage, the enforcement process may become more severe.

Record Keeping

All records documenting maintenance activities, including invoices provided by third-party service contractors, shall be maintained onsite. Upon request, the user or owner shall provide documentation necessary to demonstrate that the maintenance requirements and frequencies are being met. Maintenance is necessary to ensure proper operation by preventing any obstruction, interference, or damage to the wastewater collection systems. These records are to be kept on site for three (3) years.

GREASE INTERCEPTOR

Grease Interceptor

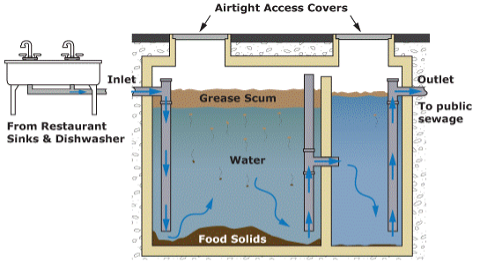

All Food Service Establishments (FSEs) that prepare food on-site in the Salt River Pima-Maricopa Indian Community are required to install a grease interceptor to prevent FOG from discharging in the wastewater collection system. There are two types of grease interceptors that are approved by SRPMIC (see below). Gravity Grease Interceptors (GGI) and Hydromechanical Grease Interceptors (HGI) are devices that are designed to catch and collect fats, oils, grease, and solids (FOGS) from wastewater flowing from commercial and restaurant kitchens. The interceptor is connected to the kitchen plumbing and is usually located below the ground and outside the building. It works by slowing down the flow of warm/hot greasy water and allowing it to cool so that the FOGS separate out and float to the top. Both types of interceptors must be trapped and vented in accordance with the International Plumbing Code (IPC).

Gravity Grease Interceptor and Requirements

A gravity grease interceptor (GGI) is generally installed in the ground outside of the facility upstream from the wastewater collection systems and are at least 500 gallons in capacity.

- Precast concrete grease interceptors are not acceptable.

- Approved grease interceptors shall be constructed of fiberglass or polyethylene.

- Shall be no smaller than a two-compartment container rated at 500-gallon capacity and no larger than a three-compartment container rated at 2500-gallon capacity.

- Any food service establishment with dishwasher regardless of number of fixtures are required to use a grease interceptor.

- Gravity grease interceptors are to be pumped at a minimum frequency of 90 days, unless an alternate frequency is approved.

- Gravity grease interceptors greater than 2500-gallons shall require engineering design.

Typical Gravity Grease Interceptor

(For Illustrative Purposes Only)

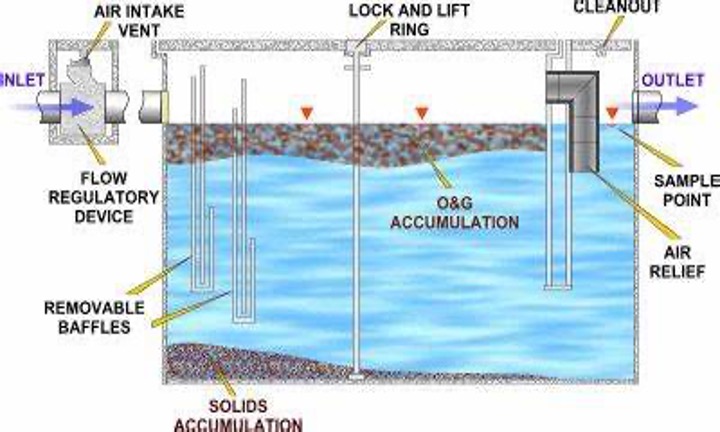

Hydromechanical Grease Interceptor and Requirements

A Hydromechanical Grease Interceptor (HGI) is a flow-based grease interceptor that is usually installed in ground or above ground, and outside or inside of the facility. FSEs generally prefer HGIs over GGIs because HGIs are less expensive to install, can fit in smaller spaces, and can be easier to maintain.

- HGIs can be located inside or outside of the facility.

- Flow restrictor is required for HGI and at no time shall the total flow through any flow restrictor(s) going to an HGI be greater than the rated flow of the interceptor.

- HGIs shall be constructed of plastic, fiberglass or polyethylene.

- Shall be rated no smaller than a 50-gallon per minute and a 100-pounds grease capacity and no larger than a three-compartment container rated at 1500-gallons capacity.

- No food waste disposal units can discharge to a HGI.

- A dishwasher may discharge to an outside HGI if it is approved by SRPMIC.

- HGIs are to be pumped at a minimum frequency of 30 days, unless an alternate frequency is approved.

Typical Hydromechanical Grease Interceptor

(For Illustrative Purposes Only)

Oil, Sand, & Water Interceptor and Requirements

An Oil/Sand/Water Interceptor (OSW) is to intercept free oils/sand by reducing the flow and waves flow patterns that is usually installed in ground or above ground, and outside or inside of the facility, such as vehicle maintenances, car washes and parking lots.

- OSWs can be located inside or outside of the facility.

- OWSs shall be constructed of plastic, fiberglass or polyethylene are acceptable.

- Shall be rated no smaller than a 50-gallons volume capacity.

GREASE INTERCEPTOR SIZING & INSTALLATION

Grease Interceptor Sizing

Gravity Grease Interceptor Sizing

Gravity grease interceptor sizes are based on capacity in gallons and the minimum size allowed is 500 gallons in capacity.

- Calculate the DFUs by adding together the Drainage Fixture Units (DFUs) for each grease bearing fixture. A Drainage Fixture Unit (DFU) is a unit of measure for the load-producing effects on a plumbing system from different kinds of plumbing fixtures.

- Calculate the flow rate in gallons per minute (gpm) by dividing the total DFUs by 2.

- Calculate the GGI size in gallons by multiplying the flow rate by 30 minutes retention time equal in gallons of the interceptor size.

Hydromechanical Grease Interceptor Sizing

Hydromechanical grease interceptor sizes are based on flow rate and grease capacity. HGI shall be rated no smaller than a 50-gallons per minute and a 100-pounds grease.

- Calculate the DFUs by adding together the Drainage Fixture Units (DFUs) for each grease bearing fixture.

- Use Table 9-2 to determine the flow rate in gallons per minute (gpm) by using the total DFUs or use Table 9-3 by using the diameter of grease interceptor inlet pipe size in inches.

- Calculate the number of meals per day by multiplying the number of seats by 4, average table turns per day.

- Use Table 9-4 to determine the grease production value for the facility.

- Calculate the total grease production pounds per day by multiplying the total number of meals serve per day by the grease production value of the facility.

- Calculate the pumping frequency number of days by dividing the HGI grease capacity pounds by the grease production pounds per day generated by the facility.

Oil, Sand, & Water Interceptor and Requirements

Oil/Sand/Water interceptor sizes are based on capacity volume in gallons and the minimum size allowed is 50 gallons in volume capacity. The following formula can be used to size the required oil/sand/water interceptor;

- Calculate the square footage of the facility areas that drain to the interceptor (ft2).

- Use Table 10-1 to determine the Treatment Capacity Factor for the type of facility.

- Calculate the volume of the OSW interceptor by using the above formula.

Approved Grease Interceptors

| Gravity Grease Interceptor models: | Hydromechanical Grease Interceptor models: | Oil/Sand/Water Interceptor models: |

|---|---|---|

| Shier GGI-750 | Shier GB3 | Park USA – Oil Trooper |

| Shier GGI-1000 | Shier GB-50 | Zurn Proceptor |

| Shier GGI-1500 | Shier GB-75 | STRIEM OT |

| Shier GGI-2000 | Shier GB-250 | |

| Zurn Proceptor (approved models) | Shier GB 500 | |

| Park-USA GTF-BG | Shier GB-1000 | |

| Shier GB-1500 | ||

| Zurn Fog-ceptor Z50H | ||

| Zurn Fog-ceptor Z75H |

Grease Interceptor Installation Guidelines

- Proper installation of a grease interceptor is crucial to its effectiveness and longevity.

- The grease interceptor should be located as close to the source of the grease as possible and sufficient clearance for maintenance and inspection.

- Follow the manufacturer’s installation instructions and use the recommended and proper fittings and connections.

- Connect the grease interceptor to the plumbing in accordance with the International Plumbing Code (IPC).

- DO NOT install air gap on the outlet side of the grease interceptor.

- Test the grease interceptor in accordance with manufacturer’s instructions to ensure it is functioning properly and there are no leaks or backups.

- The Grease Interceptor Standard Detail (DETAIL NO. 4400) could be downloaded in the Pretreatment Library Tab.

GREASE INTERCEPTOR MAINTENANCE

Maintenance of Grease Interceptors

Grease Interceptors require routine maintenance to ensure proper operation. It needs to be pumped out completely and cleaned. Routine pumping and cleaning must use mechanical cleaning methods and must be performed by a licensed and approved pumper. The grease interceptor must be left completely empty upon the completion of the pumping and cleaning. The FOG mat, liquids, solids and etc. must be removed and disposed of at a licensed waste disposal facility. In no circumstances should the pumper reintroduce the removed waste back into the interceptor or in the wastewater collection system. The use of chemicals, enzymes, proteins, grease solvents and etc. to temporarily dissolve fats, oils and grease is prohibited. Maintenance of the grease interceptors is the sole responsibility of the facility or property owner. All maintenance activities must be documented on the yearly log. The past three (3) years of all maintenance records and yearly logs must be kept on site and to be available during inspection.

Gravity Grease Interceptors Maintenance Requirements

- Gravity grease interceptors are to be fully pumped out and cleaned at a minimum frequency of 90 days and no more than 180 days without maintenance.

- Depending on the actual rate of grease accumulation and any issues found during inspection, the interceptor may need to be pumped more frequently. An alternate frequency must be approved by SRPMIC Public Works Department.

Hydromechanical Grease Interceptors Maintenance Requirements

- Hydromechanical grease interceptors are to be fully pumped out and cleaned at a minimum frequency of 30 days and no more than 90 days without maintenance.

- Depending on the actual rate of grease accumulation and any issues found during inspection, the interceptor may need to be pumped more frequently. An alternate frequency must be approved by SRPMIC Public Works Department.

- Users shall not self-clean a hydromechanical grease interceptor without prior written approval.

Oil, Water, & Sand Interceptors Maintenance Requirements

- Oil/Sand/Water Interceptors are to be fully pumped out and cleaned at a minimum frequency of 180 days.

- The interceptor shall be pump and cleaned more frequently if any coating of oil and/or sheen is visible in the final compartment and/or when the solids content reaches 25% of the interceptor/separator volume.

BEST MANAGEMENT PRACTICES

Kitchen Best Management Practices (BMPs)

The following Best Management Practices (BMPs) are simple steps that can be taken to prevent FOG from entering into the sewage plumbing. The FSE is required to implement kitchen BMPs at each facility. Implementing BMPs can save money by preventing blockages and back-ups in the FSEs private sewer line and helps to reduce FOG accumulation in grease interceptors reducing the need for more frequent maintenance activities.

| BMP | Reason For | Benefits to Restaurant |

|---|---|---|

| Train staff about how they can help ensure BMP’s are implemented. | Staff are more willing to support an effort if they understand the basis for it. | BMP’s will have a better chance of being implemented. |

| Post “No Grease” signs above sinks and on the front of dishwashers. | Signs serve as a constant reminder for staff working in the kitchens. | Minimizes grease discharge to the traps/interceptors and reduce the cost of cleaning and disposal. |

| Scrape and “dry wipe” pots, pans, and dishware prior to dishwashing. | By scraping and “dry wiping” kitchenware into the garbage receptacles, the material will not be sent to the grease traps/ interceptors. | Reduces the amount of material going to the grease traps/interceptors, will require less frequent cleaning, and reduces maintenance costs. |

| Dispose of food waste in the trash, not down the drain. | Reduces line blockages or any additional burden on grease traps/ interceptors. | Disposing of food waste in the trash will reduce the frequency and cost of grease trap/interceptor cleaning and may prevent line blockages. |

| Use a three-sink dishwashing system, which includes sinks for washing, rinsing, and sanitizing. Use water temperatures less than 140° F. | The three-sink system uses water temperatures less than 140° F, whereas a mechanical dishwasher requires a minimum temperature of 160° F. | The FSE will reduce its costs for the heating the water for the mechanical dishwasher and for operating the dishwasher. |

| Use water temperatures less than 140° F in all sinks, especially the pre-rinse sink before the mechanical dishwasher. | Temperatures in excess of 140° F will dissolve grease, but the grease can re-congeal or solidify in the sanitary sewer collection system as the water cools. | The FSE will reduce its costs for the energy – gas or electric – for heating the water. |

| Recycle waste cooking oil. | There are waste oil recyclers operating in the local area. This is a cost recovery opportunity. | The FSE may be paid for the waste material and will reduce the amount of garbage it must pay to have hauled away. |

PLAN SUBMITTAL REQUIREMENT

SRPMIC Plan Review

Plan Submittals Shall Include

Any food establishment, commercial kitchen, commercial, industrial, agricultural and managed property that will or may require a pretreatment device is required to submit design documents for plan review. This applies for all new installations, renovations and upgrades to existing systems.

In general, submittal of design documents shall include:

- The plumbing floor plans and schematic plans for the grease waste lines to pretreatment devices.

- The plans should also show that all Grease Bearing Fixtures (GBF) are routed to appropriately sized grease interceptor(s) and a plumbing fixtures schedule.

- Show all GBF on the plans that are within the facility, including floor sinks, floor drains, mop sinks, trough sinks, trough drains, pre-wash sinks, prep sinks, pot sinks, dishwashers, etc.

- The name of the manufacturer, the model number and size of the pretreatment device.

- The grease interceptor sizing worksheets:

- Gravity Grease Interceptor – GGI Sizing Worksheet-Final.

- Hydromechanical Grease Interceptor – HGI Sizing Worksheet-Final.

- Oil/Sand/Water Interceptor – OSW Sizing Worksheet-Final.

Design Criteria for Pretreatment Devices:

- GGI shall be no smaller than a two-compartment container rated at 500-gallons capacity and no larger than a three-compartment container rated at 2500-gallons capacity.

- GGI greater than 2500-gallons shall require engineering design.

- HGI shall be rated no smaller than 50-gallons per minute and a 100-pounds grease capacity and no larger than a three-compartment container rated at 1500-gallons capacity

- Oil/Sand/Water Interceptor shall be rated no smaller than a 50-gallons volume capacity.

- The grease interceptor must be an approved model from Salt River Pima-Maricopa Indian Community, Public Works Department.

- Precast concrete or metal grease interceptors are not acceptable. Grease interceptors shall be constructed of plastic, fiberglass, polyethylene or SRPMIC approved.

- Grease interceptors shall have a grease efficiency removal rate of 95 percent or greater.

- SRPMIC reserves the right to accept or decline any make, model or size of grease interceptor.

PRETREATMENT LIBRARY

Guidance Documents

Standard Details

Forms

Brochures

Contact Us – Public Works Department

Customer Service | Phone: (480)-362-5600 or Email: PwCustomerService@srpmic-nsn.gov

Water Resources Section Pretreatment | Email: PwWaterResourcesPretreatment@srpmic-nsn.gov